The use of robotic soldering cells is rapidly becoming more common within many electronic production facility’s. Once set and calibrated the machines offer both consistent accuracy and a high throughput which can greatly enhance both the company’s production yield and its flexibility to customers’ requirements.

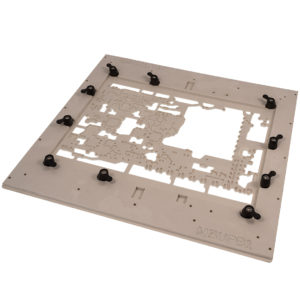

To ensure repeatability and overall accuracy individual tooling must be designed and manufactured to present the printed circuit board in the same position during each cycle, the tooling should be robust enough to support the board to prevent bowing and warpage but well designed to facilitate easy change over and bed alignment.

Key Product Features and Benefits:

– Individual base plates designed to suit each robot manufacturer.

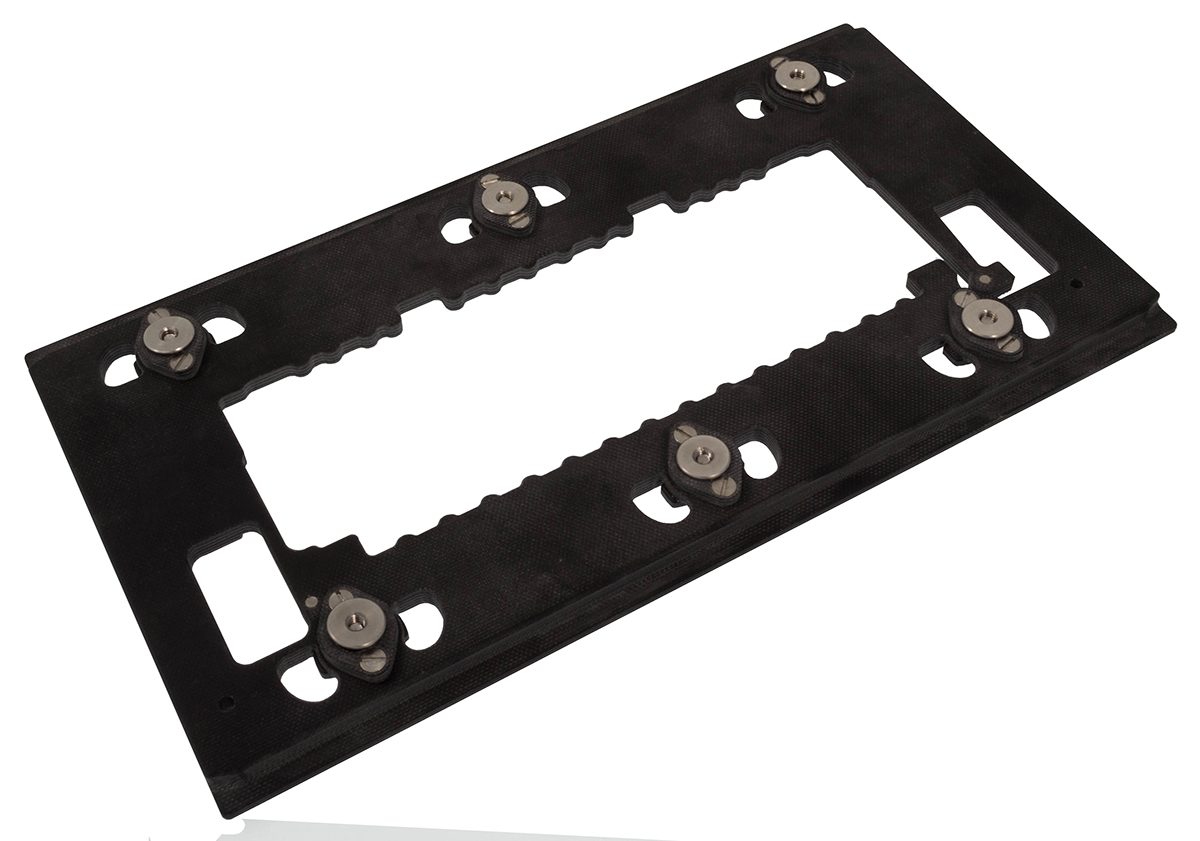

– Quality designed and manufactured direct from PCB CAD files.

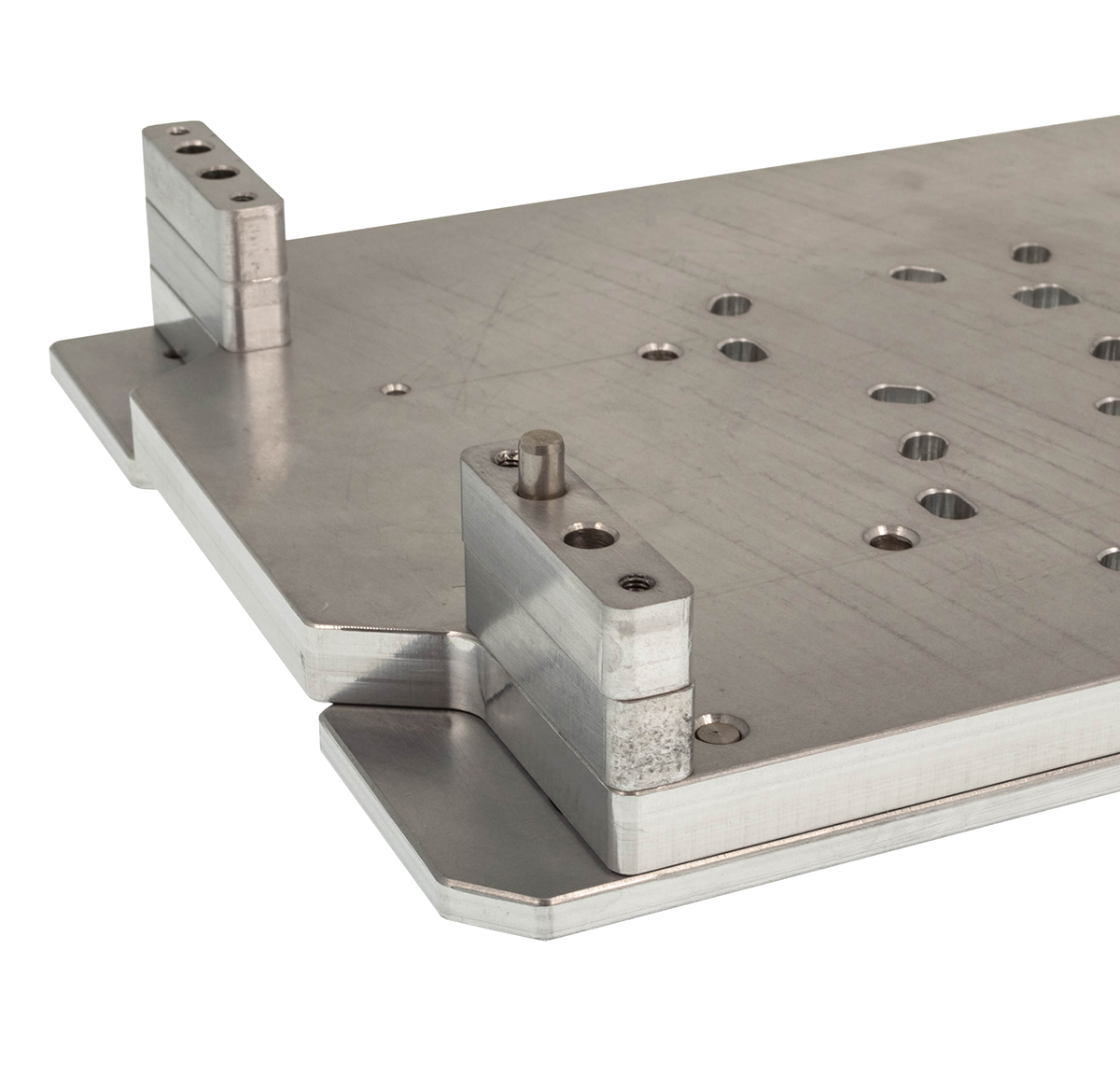

– Machined from Aerospace Aluminium.

– Close maching tolerances to suit individual component layout.

– Precision alignment of top and bottom plates.

– No distortion

– Offers repeatable soldering process.

– Low cost of ownership.

– Fast turnaround from approved design

Reviews

There are no reviews yet.