Puralloy® Grade D 30/70 is a leaded solder alloy incorporating lead and tin, with a melting range of between 183-257°C. This leaded alloy is used in a variety of industrial soldering applications, from plumbing to vehicle restoration, particularly within the process of Lead Loading. Many Vehicle Restoration Engineers show preference for using Grade D for lead loading, over the more modern two pack Resin systems, due to its greater durability, malleable nature, and suitability for deeper filling. Grade D’s wide operating temperature further gives the engineer the possibility to wipe and form the solder joint before solidification. Incorporating a lower tin content than other leaded industrial alloys, Grade D offers a more cost-effective option for soldering. For soldering to brass or copper alloys, Bakers Soldering Fluid should be considered.

Key Features & Benefits:

– Leaded Solder Alloy

– BSEN29453 Alloy Number 15

– Melt Point – 185-257°C

– Ideal for Industrial & Vehicle Restoration applications including Lead Loading

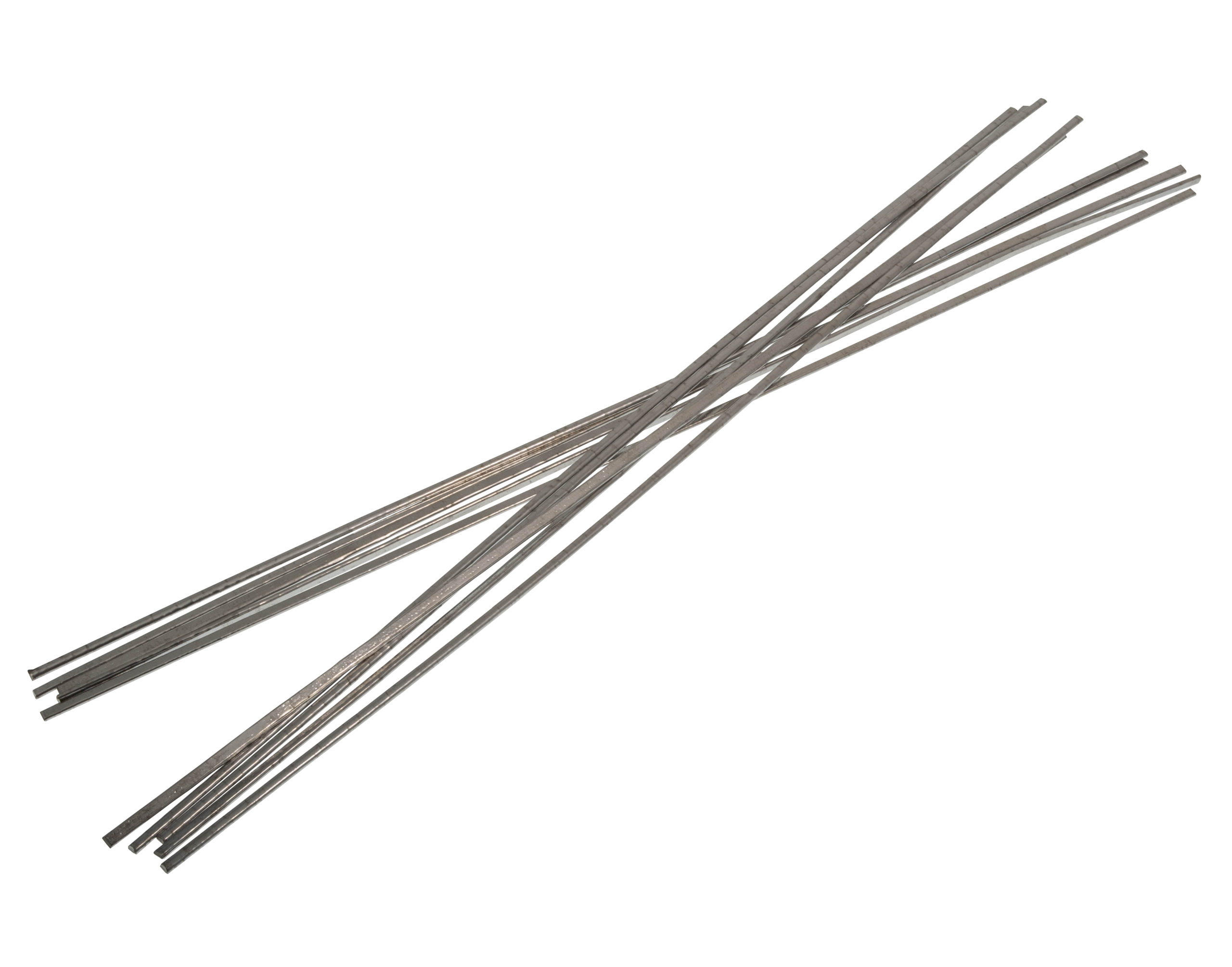

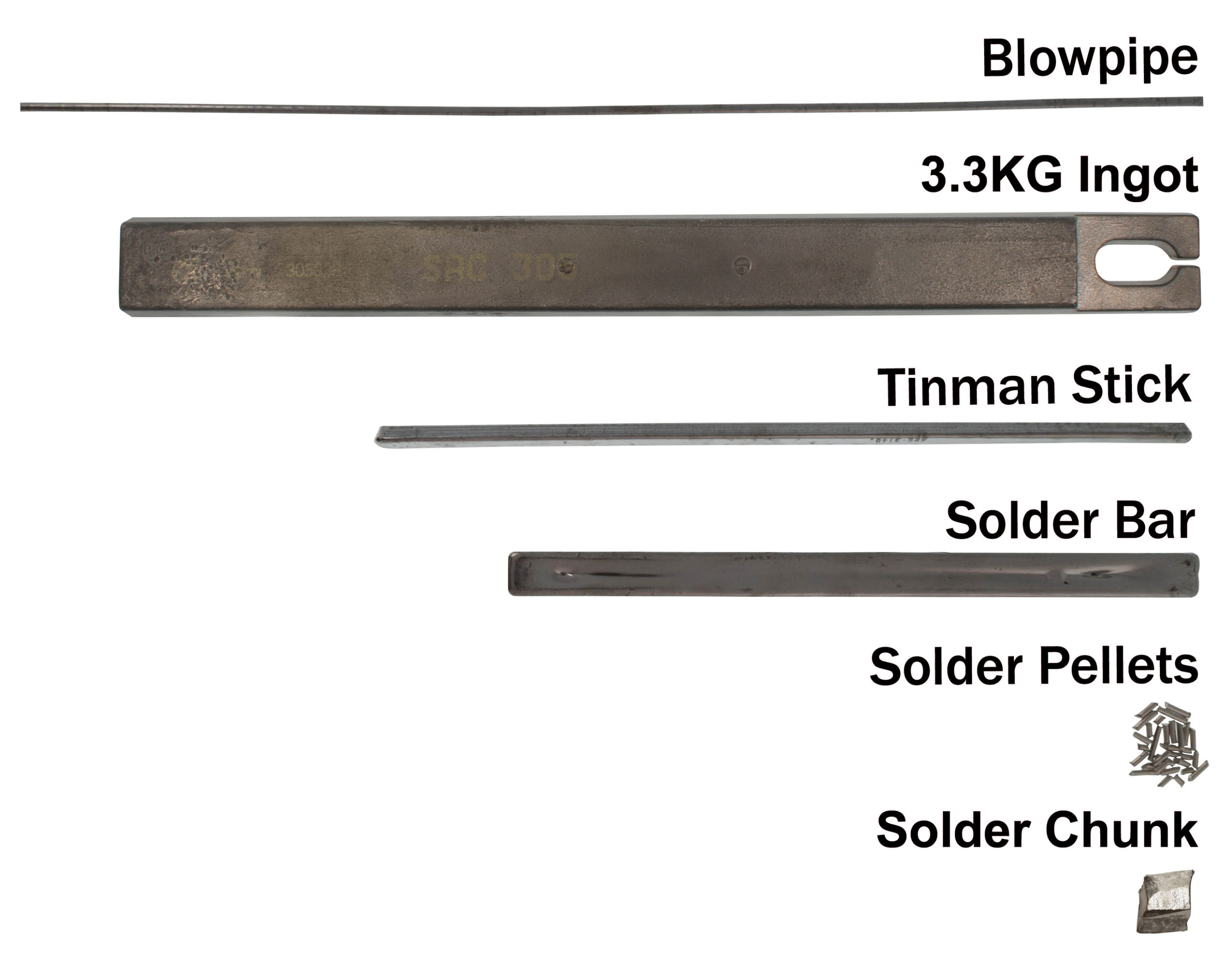

– Available in a range of formats including Bar, Tinman Sticks, Blowpipe and Feed Wire

Technical Properties:

– Density 9.72 g/cm3

– Electrical Resistivity 0.185micro-ohms/M

– Thermal conductivity 41W/m/K

– Tensile Strength 350 Kgf/cm2

– Tensile Elongation 18%

– Brinell Hardness 12MB

Reviews

There are no reviews yet.