Vapor Phase Soldering, is also known as Condensation Soldering and uses Galden® fluorinated fluids which act as a heat transfer medium when it emits controlled thermal energy during its phase change from gas like to solid state. This phase change (Condensation) on the surface of the soldering substrate will last until the assembly has reached the temperature of the vapor, commonly 215 or 230 degrees centigrade.

Due to the high vapor density of Galden® Fluids and the condensation process the complete heating-up process takes place at an oxygen free environment. Vapour phase is considered to have process advantages over convection in terms of giving control and stability over the reflow cycle ideal for special applications such as high mass, densely populated or complex printed circuit boards.

Following advantages are resulting with these physical principles:

– Fluorinated Fluids exhibit a constant boiling point, eliminating overheating possibilities.

– Vapour Phase soldering is oxygen free soldering takes place within an inert atmosphere.

– Reduced operating costs when compared to forced air or convection ovens.

– Does not differentiate between small or large devices.

– Galden Fluids are RoHS compliant

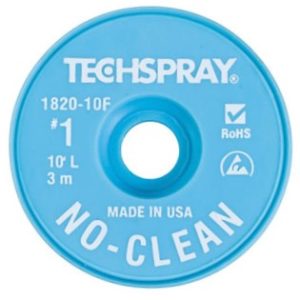

Compatible with Vapour Phase Soldering (Pictured) from Altus Group.

Key Product Features & Benefits:

– Wide choice of grades with different boiling point

– Widest operating temperature range to optimize VPS process

– Maximum process stability and repeatibility

– No corrosion or reaction with materials of construction

– Pre-heating and heating processes take place in an inert atmosphere

– Rapid and residue free drying

– Excellent thermal and chemical stability

– Narrow molecular weight distribution

Reviews

There are no reviews yet.