TB2217L is a one component epoxy resin, which has been specifically developed for surface mount assembly. This adhesive is designed to keep the components in position during both placement and the wave soldering process. It works well in fast application processes due to its low temperature curing schedules (Heat curing initiated at just 80ºC) and is ideal for temperature-sensitive components. TB2217L produces an excellent deposited dot, excellent tack strength, and after curing exceptional bond strength.

Its properties are designed for ease of handling to enable use in automated assembly by either syringe or screen print application.

Meets the requirements of IPC SM817, TM-650 Method 2.4.42.1: R-1206 on bare FR4 board supported 60 seconds above solder bath at 260°C and dipped for 10 seconds.

Availability:

13g Syringe (Internal SKU: CH-193-257 )

40g Syringe (Internal SKU: CH-193-253 )

370g Syringe (Internal SKU: CH-193-254 )

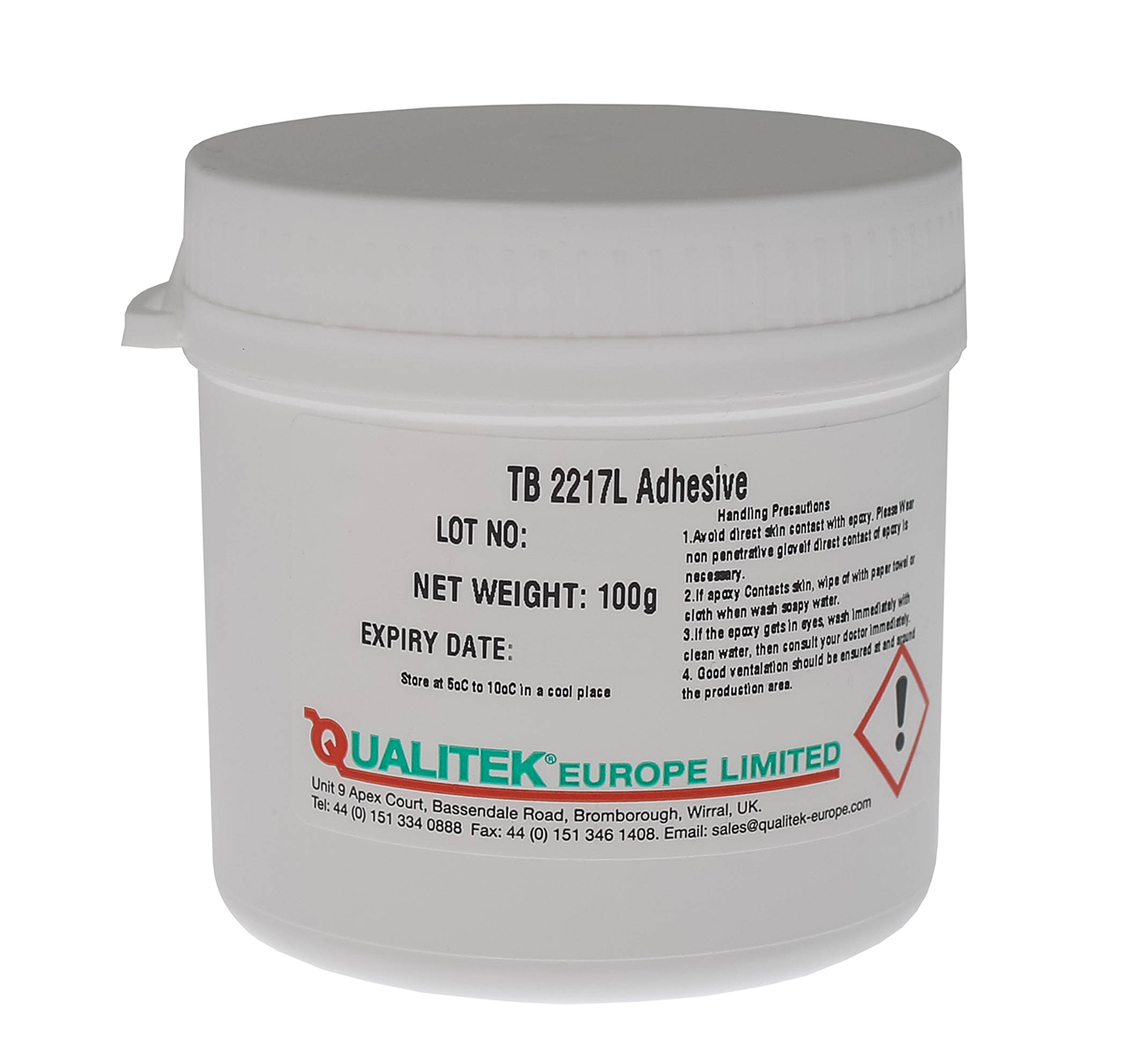

100g Pot (Internal SKU: CH-193-279 )

Key Product Features & Benefits:

– Supplied in a range of syringe sizes (13g, 40g, 370g) and a 100g Pot.

– Heat curing initiated at just 80ºC.

– Hardens in less than 60 seconds at 150ºC.

– Low temperature cure schedules.

– Minimal shrinkage and outgassing.

– Good electrical properties.

– Good chemical and thermal resistance.

– No cobwebbing, no dispenser feeding problems, excellent process ability.

– Meets the requirements of IPC SM817

Typical Curing time:

@ 80°C : 200-230 seconds

@ 100°C : 70-100 seconds

@ 120°C : 50-80 seconds

@ 150°C : 35-65 seconds

Reviews

There are no reviews yet.